Table of Contents

Outdoor Kiosk Cost Solutions

Introduction

The outdoor kiosk introduces a slew of variables including water, humidity, cold, heat, sunlight, dust, airborne particles, chemicals, and other elements which produce corrosion. Little animals that like to nest in them is another. NEMA, IP65, UL standards come into play. Getting power is just one of the crucial details as well as internet access. How Much Does an Outdoor Kiosk Cost? Also checkout Kiosk Price – How Much Does A Kiosk Cost? For a general baseline, you can factor an additional 75% more in cost for a truly outdoor-rated kiosk ($4000 kiosk becomes $7000). You can reduce that by mitigating environmental factors such as adding a canopy but that has costs too.

If you have questions then feel free to contact [email protected]

Outdoor Kiosk Manufacturers

- Olea Kiosks

- Pyramid

- KIOSK Information Systems

- LG-MRI – BoldVu® displays are built not simply to survive, but to thrive in outdoor environments.

- Peerless AV

- REDYREF – standard and custom kiosks

- Keyser Outdoor Menu Boards and Kiosks

- Kiosk Innovations

Recent Outdoor Kiosk News

- How Much Does an Outdoor Kiosk Cost?

- https://www.visionect.com/blog/e-paper-extreme-weather/

- Outdoor kiosk bill pay in OK

- No Contact Outdoor Payment Kiosk in MA

Certifications

Unless UL is specifically requested by the customer, kiosk companies and others will simply follow their own best practices. Being formally certified can be an additional $10K + time. In many situations customers writing RFPs will specifically call out UL certification. An example is outdoor requirements for outdoor smart city terminals. LinkNYC or IKE terminals likely have the UL outdoor certification if only for liability considerations. The legacy specs are 60950-22 and they have been superseded by 62368-1.UL_Consumer_technology_overview_brochure_2022_ENG-compressed

Outdoor Kiosk Considerations include:

Outdoor Design for the elements: The kiosk should be designed from the ground up as a watertight enclosure, with watertight seams and insulated inner walls to protect internal devices from heat and cold. Your provider can consult on building to the appropriate NEMA rating, with guidelines on combining the appropriate HVAC / shelter elements for the deployment environment. NEMA ratings relate to the severity of weather exposure anticipated (operating temperature range requirements, sheltered vs. direct water contact, etc.). Usually it is NEMA4 but for corrosive it becomes NEMA4X. For design considerations for all environmental specs we recommend reviewing relevant NEMA and more standards by TECA on Design Considerations page. Also here is another nice table.

Below is a video of a water ingress test demonstration Insight Touch performed on one of its outdoor units.

NEMA Ratings:

NEMA ratings are often available for devices such as A/C/Heating for kiosks. Imagine a parking kiosk in a garage and the chemicals it will be “splashed” with.

NEMA-12: Type 12 enclosures are intended for indoor use primarily to provide a degree of protection against dust, falling dirt, and dripping non-corrosive liquids. Applies to AHP & FHP models.

<Source: NEMA Publication N0. 250, Part 1, Page 1

NEMA-4: Type 4 enclosures are intended for indoor and outdoor use primarily to provide a degree of protection against windblown dust and rain, splashing water, and hose directed water. TECA products with the “XE” designation use sealed fans, sealed components, stud/gasket mounting and Mil- Spec finishes. They are designed to maintain the enclosure rating and perform in the rated environment. Applies to AHP-XE & FHP-XE models.

Source: NEMA Publication N0. 250, Part 1, Page 1

NEMA-4X: Type 4X enclosures are intended for indoor and outdoor use primarily to provide a degree of protection against corrosion, windblown dust and rain, splashing water, and hose directed water. TECA products carrying the “X” designation use Mil-Spec fans, o-ring sealed power supplies, no exposed electronic components, stud/gasket mounting and Mil-Spec finishes. They are designed to maintain the enclosure rating and perform in the rated environment. Applies to AHP-X & FHP-X models.

Source: NEMA Publication N0. 250, Part 1, Page 1

UL Requirements Come into Play

- Typical RFP statement — Kiosk shall be UL 60950-22 certified – Contractor shall provide a unique UL identifier number as this will allow the City to verify the compliance.

- This spec actually went legacy in 2020 and has been replaced by 62368-1 — UL_Consumer_technology_overview_brochure_2022_ENG-compressed

- UL-60950-22-TOC

- Equipment covered

- Ambient Air

- Mains

- Earth Potential

- Voltage limits

- Limited current circuits

- socket outlet

- UV radiation

- Corrosion resistance

- Fire

- Gaskets

- Moisture

- Plants and Vermin

- Dust

- Impact Text

- Explosive risks

- ventilation

Outdoor Display Choice

Hi Brite LCDs eliminate “sunlight washout” concerns and provide the user appropriate levels of screen readability, even on the brightest days. Touch screen integration is readily available, eliminating mandatory keyboards. Further, dual-screen integration with Hi Brite LCDs affords customers low-cost advertising, branding reinforcement, and promotional attractor capabilities.

Smart City displays are typically 55″ screens and historically have been 4000 nit. Recently that has been cut back by some vendors to 2500 nit

Outdoor Heating and Cooling

Integrating the correct HVAC unit maintains the optimal temperature and humidity level within the kiosk, for peak reliability. Your provider will consult with deployers on the operational environment, making recommendations for the best cost/performance selection. Outdoor-Sizing Guide and also Outdoor-eic_understanding_heatload_ebook are useful for determining how much cooling or heating is needed. TECA Cooling is a member of the Industry Group and is highly skilled in cooling. Kooltronic has a nice sizing tool as well.

The standard units are compressor-based. Heating and cooling options include thermocouples which are smaller than compressors but also more money for less cooling..

Consider the environment. Even in a closed system there will be exposure to outside air. And the kiosk enclosure itself. Is it salty? If so you might consider stainless steel. Another option is zinc-rich primer powdercoat as well as G90 Electroplated.

Choose components wisely and engineer design your unit to maximize natural cooling and heating and you can often eliminate or at least mitigate required A/C and heating requirements.

Another heat consideration is direct sunlight in a warm climate (we are thinking Arizona, Dallas or Florida). Here is fan flow device from Panel-Brite which is a fan for cooling the touchscreen. Ventilation and smart design cannot be stressed enough.

From Panel-Brite:

Using touch screens of any kind in extremely hot temperatures usually requires extra airflow to move super-hot air out of the gap between the front of the panel and back of the touch screen.

For these types of outdoor applications, the air gap should be increased using thicker foam tape when mounting the touch screen to the panel. This gap should certainly be more than what is used for indoor applications.

A locale such as Los Angeles is not as severe as a low humidity state which surprises people

Typically units will come with air filters. They need to be maintained. Don’t adequately filter and you can end up with “isotropic” screens such as McDonalds and Samsung demonstrated. See Updated McDonalds Menu boards Failures – sometimes it is as simple as NOT changing a filter

UL Certification

A reputable firm universally designs to UL guidelines and routinely implements UL testing on first prototypes for customers who require UL Certification. UL testing is performed to certify that the units are waterproof and safe to operate rain/snow. Parallel certification testing done at the time of manufacturing can save up to 4 months in the overall project timeline. Many kiosk manufacturers can do UL certification onsite at their manufacturing facility. That saves time and money especially if the design utilizes previously certified components.

UL 60950-22 is the specific UL set of regulations for outdoor equipment. 60950-22 tests specifically for outdoor characteristics (gaskets, vermin, dustproof, UV and more), not screen brightness (though it should). It also specifies the qualified testing for water regression. KIS image below shows that pretty clearly.

Kiosk Installation

A reputable company can provide completely turnkey installation service, addressing all the unique requirements of an outdoor placement. This includes:

- Site preparation and securing required permits

- Ensuring state-specific electrical standard compliance for watertight power cables and connections

- Power connectivity preparation (underground, if required)

- Surface leveling and ground bolting of units

Outdoor ticket kiosk considerations

1. Display Brightness – since the outdoor units will be subject to direct sunlight, the actual flat panel LCD must be brighter; 350-700 Nits vs. the normal 180-200 Nits.

2. Auto-Dimming – just as you want the display brighter during sunny days you want to be able to have the display auto-dim to lower brightness during cloudy days or at night.

3. Kiosk Touchscreen – the touchscreen technology must be such that it can be fully sealed against direct rain AND it should have safety glass in front that prevents breakage and cannot be disabled by the consumer.

4. Temperature – the computer, display and other electronics must be designed for industrial, high-temperature use. The internal temperatures may reach 130° F and the components must operate at these elevated temperature levels.

5. Keyboard / Pointing Devices – must be suitable for use in wash-down environments and made robust for severe usage.

6. Material – should be metal design with industrial powder coat finish. Most indoor materials will not survive outdoors and will be subject to cracking under sun load and varying conditions.

7. Sealing – all connections, openings, doors, panels into the Kiosk must be designed with watertight gasketing, latches and fittings. Otherwise, water will get into the unit.

8. Shock / Vibration – these Kiosks will take more physical abuse than indoor versions so all electronic components need to be “shock-mounted” to prevent damage.

A kiosk for outdoors can still be designed with the same level of ergonomics and user interface to run the same applications as inside. However, different packaging methods must be employed, the electronics must be suitable for the higher shock/temperature environments and the display/touchscreen must handle the varying ambient light conditions.

Going cheap Outdoor Kiosk

Redbox tried that. They went with plain resistive “regular” touchscreens which were the cheapest available. Problem is for the outdoor the heat build up caused blackouts so first they tried mitigating with drop down flaps. Eventually they went to new sun shields. How much did all those changes and service calls cost them in the meantime? Careful going cheap. It can be the most expensive of all.

Testing the Outdoor Kiosk

What about ingression? Is there a weep hole designed into the bottom and if so does it have a check valve to prevent elements from getting into the kiosk.

Outdoor ticketing kiosk being tested at Kiosk Information Systems out in the parking lot. Click for full size image.

Resource: Bud Industries

Outdoor Kiosk and Ticket Kiosk – The Mysteries of IP65, IP66, and IP67 Rated Enclosures Explained

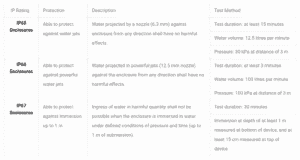

It is often confusing for an engineer to know what type of rating they need to look for when they desire to have a “waterproof” enclosure. Much like with watches or other sensitive information, there is a big difference between waterproof, water-resistant, and other descriptive but not specific labels. To help out, there are several rating systems that have been developed although and several testing agencies that verify the results. Among these, the two best known are NEMA and IP. This blog will deal only with the IP system.

For enclosures, the typical “waterproof” IP ratings are IP67, IP66 and IP65 enclosures. The chart below gives the specifics of what these ratings mean and how they are measured.

IP ratings, or ingress protection, were developed by the IEC (International Electrotechnical Commission) and are most heavily used in Europe and Asia, with some adherents in North America as well. Since these are international standards, the testing is often certified by the TUV instead of UL, although both provide stringent testing. One area to note is that while these are developed to deal with harsh environments, they do not address UV protection standards (outdoor) and the engineer should look for or ask about the ability of the enclosure to include UV protection materials.

Bud’s new PIP series combines the best of fiberglass and polycarbonate

There have been ongoing debates for years about the advantages of polycarbonate over fiberglass as a material for enclosures. Both are great for NEMA/IP boxes, often being able to reach IP67 or IP68 ratings. Here are a few advantages of each:

- More impact resistant

- Provides greater UV protection

- Easier to modify. With Fiberglass enclosures, there is a fine dust that can be irritating to the skin or when inhaled. Fiberglass also can splinter, ruining the box, if it is not modified correctly

- More visually appealing. The enclosures made from polycarbonate tend to be smoother with less texturing

- More true to shape with less mold variability. The glass particles will retain the rigidity through the production process, insuring that there is more consistency between boxes. This is very important as the installer tries to maintain their IP rating with a situation where wall thicknesses and slope can vary. This means it is much more difficult to create a tight seal between the box and the accessories

- Fiberglass may hold up better in extreme heat or cold. Polycarbonate has a tendency to shrink slightly when cold or to expand slightly in heat. Fiberglass maintains its original shape much more readily

More Posts