Table of Contents

Surface Treatment Touchscreens

Craig is a senior staff writer for Kiosk Industry Group Association. He has 25 years of experience in the industry. He contributed to this article.

Sometimes it seems the last thing we put on a touchscreen is our finger. There are so many ways to customize a touchscreen and over the years they have continued to multiply. Whether its reflections, or vandals or privacy or what…There is always something new. Women with long fingernails are problematic. The only technology I have not seen is smart proximity sensing so people can’t look at the screen over your shoulder.

Introduction

What customers want when they ask for AR coatings is to reduce the ability to see oneself when looking at the display, especially when you are outside. AR coatings make the display easier to see.

In legacy touch products, glare reduction was done using anti-glare (AG) coatings. AG treatments are made by either coating the touch surface with silica “bumps” or lightly etching the glass. The result is that some of the light hitting the touch surface is diffused or scattered, and not reflected back at the user. This was good enough for 25 years of touch technology.

Then came Apple and their beautiful high-resolution display. To preserve that super display image, polished glass was used on the iPhone instead of the traditional AG treatment. It is kind of OK for mobile devices because you can tilt the surface to reduce reflections, but less easy to “fix” on bigger devices such as pads.

So the market is asking for something that reduces reflections but preserves that pretty little picture on the display. This has traditionally been done using anti-reflection treatments. Reflection reduction can be achieved in a number of ways, including moth-eye treatments, circular polarizers, eliminating the reflective surface, or that which I will talk about, multi-layer thin film interference coatings.

AR (Anti-Reflection)

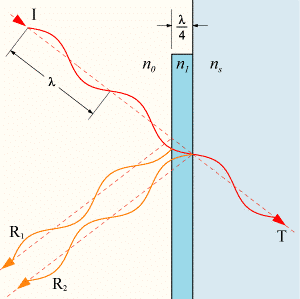

This treatment applies a film or coating of a specific thickness to the surface of a cover lens. The film reduces the reflections on the surface by canceling out a specific wavelength of light as it is reflected back to the consumer. When a specific wavelength of light passes through the AR material, some of it is reflected back to the consumer at the surface of the AR film (R1) and some of it is reflected at the surface of the cover lens (R2). The thickness of the AR film causes the reflected wavelengths (R1, R2) to be reflected exactly out of phase with each other (see diagram 1.1) so that they cancel each other out. Thus the consumer will not see their own reflection. Instead, they will see a brighter and more vivid display.

-

-

-

Problems/Fixes

- Fingerprints – The fingerprint problem has been fixed with anti-fingerprint (AF) coatings. Recalling the description above, you know that the thin film coating must be the precise thickness of a light wave (say ¼ of the width) to work. Along comes your dirty, oily fingertip, laden with hand cream, to touch the screen. Boom, the oil you left on the AR coating has changed the thickness of the coating which reduces the ability to trap the light and most often shows up as a fingerprint. AF coatings work by resisting the ability of the oil on your finger to “stick” to the AR coating; these are called hydrophobic (fear of water) coatings. Of course, for the AR coating to work, the AF coating must be built into the precise thickness of the thin-film stack. Touch Guy is not impressed with the aftermarket spray-on AF coatings over AR stacks. Not impressed at all.

- Wears Off – fact is you have an angstroms thick material in an abrasive and chemically active environment, and you have limited time before its anti-reflection properties go away, especially on frequently touched areas. There seem to be two solutions…the first is that the AF coating on the AR stack is made of (secret) tough material that will wear-off your fingertip (just kidding) before it gives up. The other is to use thicker, but less effective (2% reflection) organic AR coatings, that seem to have better resistance to finger wear. Another way around the AR wear problem is to eliminate the reflective surfaces in the first place.

- Fix: An AG coating and an optically bonded p-cap touch panel eliminates the wear, and anti-fingerprint issues, with only a minor loss in display sharpness.

-

-

AG (Anti-Glare)

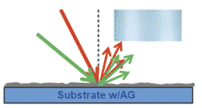

This type of treatment involves creating a rough surface on the cover lens via an etching process. As light reflects off of the rough surface, it is scattered at different angles (see diagram 1.2) which reduces the clarity of the reflected image. Thus, the consumer will not see the bright glare of any reflected light source.

AF/AS (Anti-Finger Print)

This type of treatment reduces the ability of the cover lens retaining oils from your finger. AF/AS treatment is typically applied by vacuum deposition or by a liquid chemistry process, which creates an oleophobic top coating. Since this layer is a chemical modification of the glass surface, it is very durable compared to aftermarket AF/AS spray-on films and it is very thin with little or no impact on the optical quality of the display.

It has to be noted that AF/AS treatments do not perfectly prevent fingerprints. They only cause finger oils to bead on the surface, which makes them less noticeable and also much easier to clean off the screen.

Another benefit of the AF/AS coating is the “feel” or user perception of the treated surface. Because the surface is smooth, the finger will glide more easily compared to a non-treated surface. A non-treated cover lens surface can cause the user’s finger to stick, skip, feel like it’s being dragged, or even make drawing a singular line on the screen difficult so that it becomes a dotted line.

Oleophobic Coating

An oleophobic coating is an oil repellent coating. This means that it does not allow oil to absorb. A common oleophobic substance is water, but this quality can be produced on other materials with the help of treatment processes. The most useful aspect of oleophobic coatings are that they can make materials fingerprint-resistant because they repel the oils that are produced by the skin.

Sunglasses (Yes, sunglasses..)

Some outdoor high NIT touchscreens can come with what’s called “Circular Polarization Filters”. This allows people with sunglasses to see the screen. How Circular Polarizers work.

Protection Treatment

Many outdoor touchmonitors come with Tempered Glass and Anti-Reflective.

Tablets

Many tablets (and mobile phones) come with Gorilla Glass by Corning. Here is the pitch — Tough Corning® Gorilla® Glass is enabling slimmer, more lightweight laptops, notebooks and tablets with exceptional visual quality, while providing damage- and scratch-resistance from everyday handling and use.

AntiBacterial Coating AntiMicrobial Coating

This is a touchy subject for many…We have an entire page devoted to this subject. Our typical recommendation is treat it like your mobile phone, but better. Clean it everyday. There are excellent cleaners like PDI Easy Screen. Use them. It is not rocket science and oily, dirty, unwashed hands are a fact of life. It amazes me when I go to the airport or Costco and see how many men do not wash their hands leaving the lavatory. See AntiBacterial Coating page

UV Treatment

We have some experience here having won an award for developing such a system. These systems though are not to be taken lightly; there are liabilities that come with them. If you want to utilize UVB light treatment we recommend having employees manually do it off-hours when they are cleaning the screens. A high quality (and safe) manual system is less than $500.

ADA and Accessibility Touchscreen Access

One of the considerations for Accessibility is with Prostethics. Some touchscreen technology does not work since there is no path to ground. PCap for example. For those situations we recommend Resistive or Infrared touchscreen technology.

Privacy Screens for HIPAA and Privacy

Here is an example of kiosks with privacy screens on them. Typically 3M is the most popular. There are two-way and four-way screens and they act like windows blinds basically. They orient generally horizontally but they can also do vertical.

More Site Related Information

https://newvisiondisplay.com/glass-treatments-touch-screens/

http://www.en-touch.com/what-is-an-oleophobic-coating/

http://www.crizal.ca/en/the-benefits-of-crizal/smudge-resistance/

https://www.corning.com/gorillaglass/worldwide/en.html

https://www.photodon.com/blog/archives/how-are-privacy-filters-made-and-how-do-they-function

Contributing Companies

- Olea Kiosks

- New Vision Display

- Touch International

- Hoya Filter

- Corning Glass